Tooling

Precise Virtual Tryout of 3D Tooling

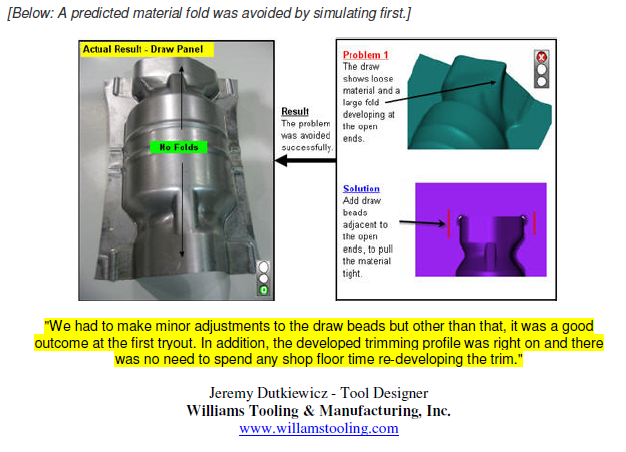

Before any tool steel is cut, advanced incremental simulation technology is used to validate a tool design. Full incremental simulation is the final check before tooling data is released to the shop floor for tooling manufacture. Without final validation in simulation, a tool design is just a best guess. Unexpected results are avoided when tool designs are simulated and validated in the virtual world.

Accurate Blank and Trim Development

Simulation technology has evolved and blank or trim development is no longer a manual process. Based on simulations of actual 3D tooling data, blank and trim developments are iteratively calculated automatically, until a desired tolerance is achieved. This means the simulation is run multiple times, and at the end of each run the blank or trim error is measured and then fed back in to the cutting steps, automatically. The blank or trimming curves are automatically adjusted and the simulation repeats. Sounds like how we used to do it on the shop floor! But by using simulation technology, the development is determined in a few hours, not a few days or weeks.

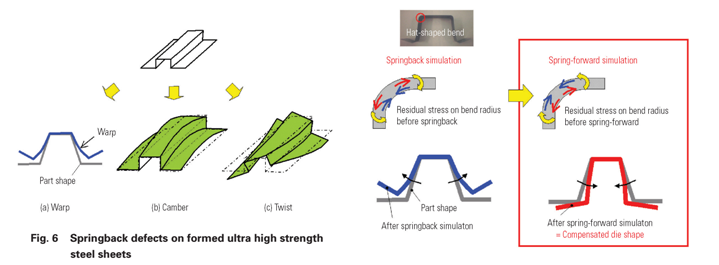

Integrated Springback Compensation

The challenge of advanced high strength steels (AHSS) is upon us. Dual Phase (DP) and Triple Phase (TP) steels are becoming more common. In addition to formability concerns, springback is a major challenge. Using simulation we can not only predict the magnitude and direction of springback in 3D, we can also apply springback compensation (overbend) strategies to counteract springback problems. Often multiple re-cuts of a tool are required to achieve the required tolerance. Using simulation significantly reduces the number of shop floor re-cuts to achieve the desired results. A typical results may be that without simulation, 7 or 8 re-cuts were required, but with simulation the same result is achieved in 2 re-cuts.